An anti-lock braking system (ABS) is fitted as standard to all modern day cars as an additional safety measure. Under heavy braking, the force exerted on the brake discs can cause the wheels to lock, resulting in the car skidding along the road surface. This sudden loss of traction may cause the car to decelerate less resulting in possible impact.

ABS works by detecting wheel lock (based on a wheel suddenly stopping compared with what the car is actually doing). In order to do this, ABS rings are fitted behind each wheel which look like cogs. As they rotate, they 'strobe' past a sensor. If all four wheels are rotating at a similar rate then the controller will calculate that all is well. Should the speed measurement from one of these sensors suddenly fall to zero, then the wheel must no longer be rotating (i.e. locked up).

To mitigate this issue, the ABS system effectively applies and releases pressure to the brakes very quickly in order to regain traction and carry on stopping the car.

On mk1-6 cars, the ABS system was combined with the 'Trust' and 'Trust+' stability system which also looked at the cars behaviour in more than one dimension. The mk7 fortwos combined ABS with ESP resulting in an even more sophisticated stability system.

Should an ABS ring fail, incorrect speed readings will be sent to the ABS controller. This may result in the ABS operating every time you brake or simply just bring on the ABS (and/or warning triangle) on the dash. As a first port of call, you should check the ABS rings (also know as Reluctor Rings) when attempting to diagnose any braking problems.

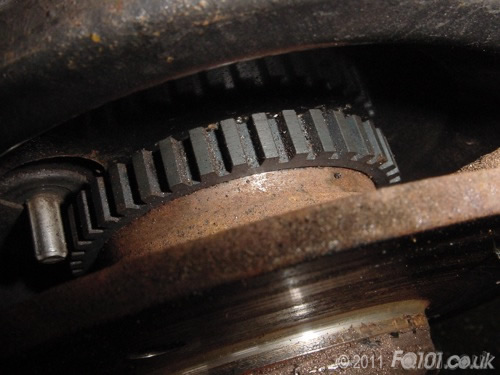

Front ABS rings

The front ABS rings are mounted on the hub of the wheel bearing. They are hidden between the brake disk and a steel plate. As such, they are protected from the elements and rarely corrode to the point of failure. Here, you can see the location of the ABS ring and the associated sensor:

Whenever you change the brake discs, it is good practice to brush any debris away from the ABS ring with a brush.

As you can see, corrosion is minimal. This image was taken on a 6 year old car. It is likely that the wheel bearing will fail before the ABS ring resulting in replacement of the whole assembly.

Rear ABS rings

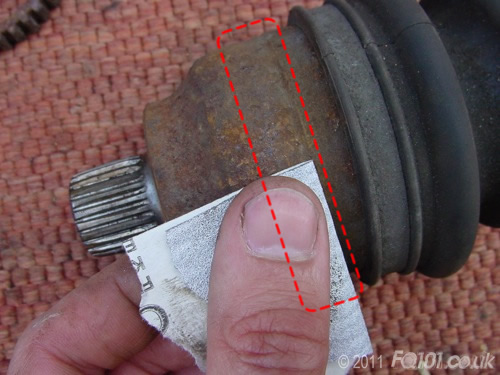

These are where problems are common. The rings are located on the rear driveshafts before they connect with the wheel hubs. They are very exposed to the elements and unfortunately weren't made of high quality material. In the following image, we have disconnected a driveshaft from the hub to show the extent of corrosion. You can see a clear brake where rust has built up under the ring and forced it to split. This will be transmitting an irregular speed to the controller as the car is moving causing the ABS light to come on constantly.

The only real solution is to replace the ABS ring or entire driveshaft. ABS rings are not available from smart but there are several companies online who can provide high quality ones with corrosion resistance built in.

To replace the ABS ring we recommend removing the driveshaft from the car. Information on how to do this can be found here.

Now that the ABS ring has cracked, it will remove from the drive shaft fairly easily. We found that forcing it open at shown broke any persistant rust patches.

Your new ABS ring need to have 42 teeth and an internal diameter of 68.8mm.

With the old ring removed, give the surface of the driveshaft a good clean. Dislodge any flakey rust patches with a file or wire brush. Then clean off surface rust with some course sand paper.

Offer up your new ABS ring. If it doesn't wedge easily on the wide part of the drive shaft, remove and give the surface another clean. Use a metal file to take the surface down slightly. Don't go mad though! You want the ABS ring to be held in place with a good 'interference fit'.

With the new ring lined up, tap into place with a hammer. Using the old ring provides some sacrificial protection to the new one.

When you are happy that you have driven the new ABS ring along the driveshaft enough, you can now refit the driveshaft to the car.

Give the ABS sensor a quick clean as you reassemble everything. Then check operation with a quick drive. The ABS light should stay off. If not, try disconnecting the battery briefly and try again.

If you want your ABS rings to last even longer, you can corrosion treat the whole driveshaft. Use a suitable anticorrosion product (Waxoyl works). Don't use Hammerite as you'll find that it doesn't last. The following shafts were thoroughly clean and coated in a silver marine grade paint.